- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why Is the Monochrome Low-Voltage Light Strip Becoming the Go-To Choice for Modern Lighting?

A monochrome low-voltage light strip is an LED tape that emits a single, fixed color (for example, warm white, cool white, red, green, or blue) while operating at a low DC voltage (commonly 12 V or 24 V). Unlike RGB or tunable strips, the monochrome variant offers consistent, uniform light output without color mixing or shifting.

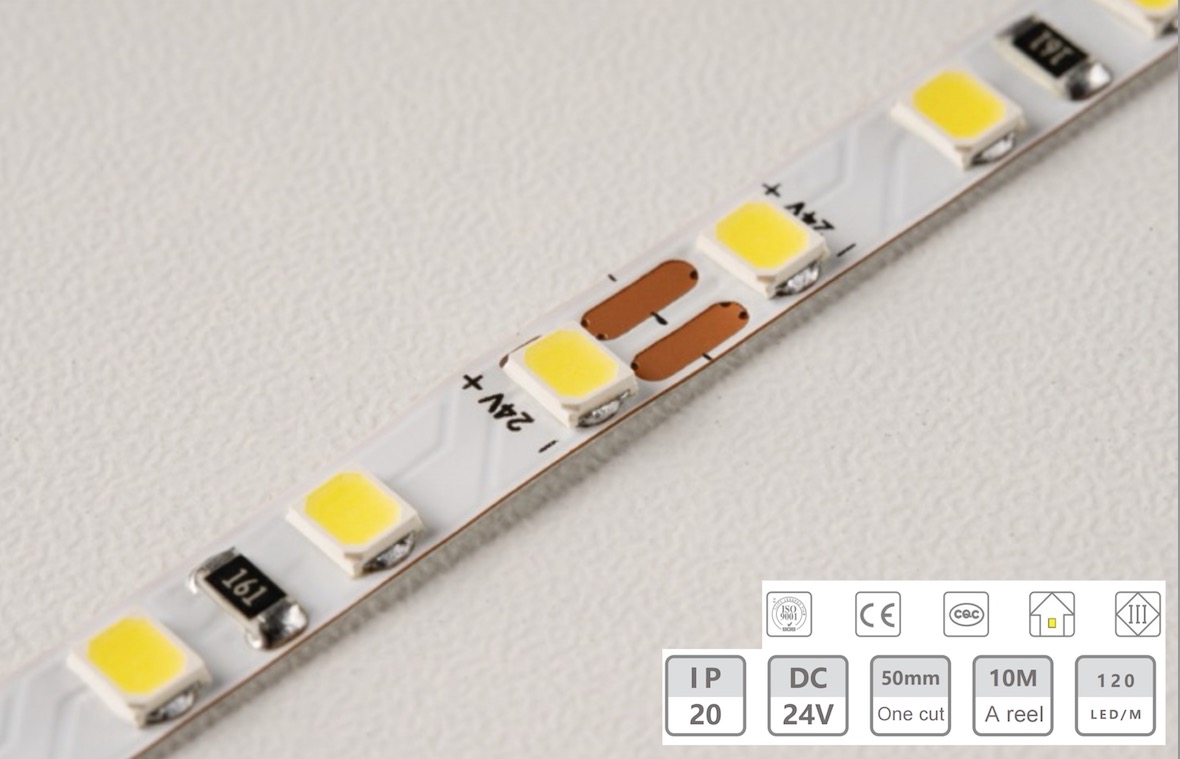

Key Specifications of a Typical Monochrome Low-Voltage Light Strip

| Parameter | Typical Value / Range | Notes & Significance |

|---|---|---|

| Input Voltage | 12 V DC or 24 V DC | Low voltage is safer for handling and allows modular system design |

| Power Consumption | 3 W to 15 W per meter (varies) | Depends on LED density, efficiency, and brightness |

| Luminous Flux | ~300 to 1,200 lm/m | Based on LED bin, efficacy, and design |

| Color / Wavelength | e.g. 2700K, 3000K, 4000K white, or 630 nm red, etc. | Fixed (monochrome) output without RGB mixing |

| Beam Angle | 120° (typical) | Wide coverage, uniform spread |

| Cut Interval | Every 5 cm or 10 cm | Allows field customization |

| IP Rating Options | IP20 (non-waterproof) / IP65 / IP67 / IP68 | Enables indoor or outdoor use |

| Lifespan / MTBF | 30,000 to 70,000 hours | Depends on thermal management and current control |

| Dimming / Control Mode | PWM / analog 0–10 V / PWM + 0–10 V interface | Compatible with many control systems |

With a clear understanding of these specs, the following sections explore deeper.

Technical Profile and Core Advantages

Monochrome vs Other LED Strips

Monochrome strips differ from RGB, RGBW, or addressable LED strips in that they emit only one color. This fixed color design ensures consistent brightness and color stability over the length of the strip. As explained in LED technical overviews, single-color (monochrome) strips are often more efficient (fewer internal circuits, less current waste) and simpler to control.

Why Low Voltage Matters

Operating at low DC voltages (12 V or 24 V) brings multiple benefits:

-

Safety: Reduced risk of shock and easier handling during installation.

-

Flexibility: Strips can be cut, extended, or paralleled more easily, enabling customization.

-

Reduced heat & energy loss: Lower voltage drops and losses (especially over short runs) when properly sized.

-

Compatibility: Works with a wide range of controllers, dimmers, and power supplies.

That said, for very long runs, voltage drop can become limiting; appropriate gauge wire and segmentation must be planned.

Key Advantages of Monochrome Low-Voltage Strips

-

High efficiency & low power consumption: LED strips can use up to 80 % less energy compared to traditional lighting sources.

-

Uniform lighting output: No color shifts or banding across the strip length.

-

Thermal management: Lower heat output, simpler thermal design, and longer lifetime.

-

Simplified control: On/off or dimming control without complex color mixing or addressing.

-

Cost effectiveness: Lower component and control costs compared to multi-color systems.

-

Aesthetic minimalism: Ideal for elegant, minimalist lighting where one tone is desired.

-

Longevity: With good design, lifespan in the tens of thousands of hours is achievable.

Common Use Cases

-

Cove lighting in residential or hospitality interiors

-

Under-cabinet or shelf lighting

-

Accent lighting for walls, corridors, stair risers

-

Display cases, signage, retail shelf lighting

-

Architectural wash lighting

-

Outdoor accent (with proper waterproofing)

Why the Market Is Embracing Monochrome Low-Voltage Light Strips

What Market Trends Are Driving Adoption?

Minimalist & Sustainable Design Trends

Contemporary interior design increasingly favors clean lines, subdued elegance, and energy efficiency. Monochrome lighting aligns precisely with these aesthetic trends by providing discreet illumination without visual noise. In 2024, the trend toward sustainable, minimalist, and intelligent lighting systems became a defining marker.

Smart, Integrated Lighting Systems

As more buildings adopt smart control ecosystems (e.g. centralized dimming, sensor networks, IoT integration), lighting that offers stable, dimmable monochromatic output becomes a reliable backbone. This consistency is easier to integrate and predict than color-changing systems.

Energy & Regulatory Pressures

Energy codes and regulations increasingly favor LED adoption and efficiency gains. Monochrome low-voltage strips are high on efficiency and power conservation, helping to meet such mandates while delivering design flexibility.

Cost Pressure on Multi-Color Systems

While RGB and tunable systems remain popular for dynamic lighting, their complexity (controllers, wiring, demand for color calibration) introduces extra cost and potential maintenance overhead. For many installations, monochrome satisfies most functional and aesthetic needs at lower total cost and risk.

What Are the Benefits Compared to Alternatives (like High Voltage or RGB Strips)?

-

Compared to high-voltage LED strips: Low voltage is safer and easier to install, but high voltage may allow longer runs without a driver.

-

Compared to RGB / color systems: Monochrome is simpler, more stable, less complex — no color mixing errors, fewer components, more predictable output.

-

Compared to traditional lighting: Much better energy efficiency, lower maintenance, smaller form factor, longer lifecycle.

Thus, the rationale for adoption is strong: safety, efficiency, reliability, lower system complexity, and aesthetic consistency.

Best Practices for Design, Installation, and Optimization

Planning & Design Phase

-

Segmenting & Voltage Drop Analysis

-

Calculate maximum run length per section to avoid excessive voltage drop.

-

Use thicker gauge wires or multiple feed points for long runs.

-

Consider 24 V where runs are longer since voltage drop relative fraction is smaller.

-

-

Power Supply & Driver Selection

-

Select a driver with sufficient wattage headroom (e.g. 20 % margin).

-

Match the DC output exactly (12 V or 24 V) to the strip specification.

-

Use constant voltage drivers for monochrome strips unless specified otherwise.

-

-

Dimming & Control Integration

-

Use PWM dimmers or analog dimming (0–10 V) compatible units.

-

For larger systems, centralized 0–10 V or DALI control may be desirable. (0–10 V is a widely used lighting control standard)

-

Ensure control wiring is isolated from high voltage wiring to avoid interference.

-

-

Thermal & Mounting Design

-

Mount strips on aluminum channels or heat sinks to dissipate heat.

-

Maintain at least minimal airflow in enclosed installations to avoid thermal buildup.

-

Use diffusers or cover lenses if softening or uniform light is desired.

-

-

Waterproofing & Environmental Considerations

-

For outdoor or humid spaces, choose IP65/67/68 rated strips with protective coating.

-

Seal end caps and connections with silicone or UV-resistant resin when exposed to the elements.

-

Installation Workflow and Best Practices

-

Before powering, test each run to confirm polarity, continuity, and uniform output.

-

Use proper connectors, solder joints, and strain relief on wiring.

-

Where cuts are made, respect the cut intervals and maintain proper pad connections.

-

In longer runs, feed power from both ends or supply midpoints to avoid drop.

-

Organize wiring so that control and power paths are clean and serviceable.

Commissioning and Maintenance

-

During commissioning, slowly ramp up dimming to confirm linear response across segments.

-

Document wiring, segment layouts, and driver codes for future maintenance.

-

Periodically inspect for loss in brightness or color shift (a sign of aging or overheating).

-

Replace drivers before they reach end of life to protect attached strips.

Troubleshooting Common Issues

-

Uneven brightness across the strip: Check for voltage drop—re-feed power mid-run or shorten segments.

-

Flickering when dimming: Confirm PWM frequency is high enough and drivers are dimmer-compatible.

-

Color shift or dimming drift over time: Ensure current stability, thermal control, and that the driver is within its safe operating region.

Frequently Asked Questions (FAQ) About Monochrome Low-Voltage Light Strips

Q: Can the monochrome strip be dimmed without altering the color temperature?

A: Yes. Because it emits a single fixed color, dimming via PWM or analog (0–10 V) does not shift color temperature — brightness only is adjusted.

Q: What is the typical maximum run length before voltage drop becomes significant?

A: The safe run length varies by gauge, strip wattage, and voltage. For a 12 V strip at moderate load, runs beyond ~5–7 m often require mid-point injection or segmented design. For 24 V systems, the permissible length can be somewhat longer. Always perform voltage drop calculations and provide multiple power injection points as needed.

Outlook & Brand Mention + Contact Invitation

Looking ahead, the trajectory for monochrome low-voltage light strips is increasingly promising. As smart buildings, energy efficiency mandates, and minimalist design trends converge, demand for these streamlined, high-performance lighting solutions will continue to grow. Integration into IoT and sensor networks, adoption of advanced dimming protocols, and even further improvements in LED efficacy and lifetime will push the boundaries of what a simple, monochrome strip can achieve.

Among manufacturers focusing on this niche, Kons is building a reputation for combining rigorous engineering, stable performance, elegant design, and responsive support. For projects seeking reliable monochrome low-voltage lighting solutions that align with both aesthetic and functional demands, consider Kons as a trusted provider.

Contact us to discuss tailored solutions, project specifications, or to request technical datasheets and support.